Hutchies'CustomBathrooms

#Welcome

We can spend as much as three years of our life in the bathroom. When you multiply that by every person in a household, that’s a lot of showering, shaving, shampooing, and teeth cleaning.

The bathroom is one of the highest traffic areas, a major decision factor for buyers and tenants, and the room with the highest rate of defects and maintenance demands. It’s critical for these pivotal spaces to have aesthetic appeal as well as faultless functionality right from the start. They need to look good and they need to work.

As part of our commitment to continuous improvement, Hutchies has been exploring a range of alternatives to traditional bathroom installation. We have sought innovative resolutions to the historic tension of balancing high quality form and function, while addressing cost, time, and layout constraints. Developer and or designers do not have to compromise design principles to make our customisable bathrooms work.

Using our own advanced production technology, we believe we have created a solution that will address many of the pitfalls that come with the installation of traditional bathrooms – particularly in high-density living.

TheChallenge

One of the smallest rooms in a dwelling has long been the biggest cause of problems for builders. Wet area defects represent around 60% of all building defects nationally.

Building a traditional bathroom requires the work of multiple trades, working in cramped spaces, often with low lighting and long dry times. When you consider the circumstances, it’s easy to see how things can get overlooked and mistakes made.

High density developments like hotels, units, and student accommodation feel the impact of this massive failure rate intensely. The success of these projects is dependent on consistent duplication of quality results within tight timeframes and lean budgets, leaving little room for error. Multiple defects result in inefficiencies and cost escalation that negatively impact margins at the end of the project – not to mention client relationships.

Hutchies has been contemplating the wet area predicament for some years – it’s sticking point for us, as well as our clients. After a lot of research in collaboration with clients, architects, designers, and end users, plus multiple trials, we’ve arrived at a solution that wins the construction trifecta of time, cost, and quality.

OurSolution

Hutchies offers a customised, high quality bathroom solution that uses practical installation methodologies, and delivers superior results, while working within time and budget constraints.

Our front-end design and advance configuration ensures defect-free bathrooms, installed at the most optimal time in the program. Custom production ensures faultless replication across high-density facilities – and all without compromising creative scope.

Importantly, customisation works seamlessly with the overall construction process. Although design and configuration is offsite, the overall process takes a holistic approach. At our core, we are builders, and we understand construction management in intimate detail. We work with consultants, designers, architects, and other key project stakeholders to ensure your bathroom solution is integrated with the overarching project execution methodology. We’ll collaborate with the site team to make sure we use the most practical installation procedures.

We maximise all the benefits of a production environment, including concurrent construction, resource optimisation, and expense containment. Our building services consultants and trade experts are all included in the design process to ensure comprehensive management from the outset.

While it’s not the answer for every project, Hutchies’ front-end bathroom design allows us to offer a range of options that have not been previously available, ensuring you get the best possible solution for your project.

#Custom Quality

Hutchies’ custom bathroom solutions are designed in intricate detail using 3D modelling technology. Our models get right down to the nitty gritty – screws, grout, silicone, it’s all there. Going to this level of detail in design means potential issues are easily identified and rectified in the early stages.

Detailed modelling also enables a comprehensive, all-inclusive bill of materials to be generated, which means the procurement team can accurately source all items in bulk, with less waste, well ahead of program.

Another advantage of front-end detailed design and advance configuration is the ability to build a prototype to show clients, architects, and even end users. Being able to interact with a real-life functional sample means everyone is confident about the final product – even before construction begins.

Configuring bathrooms offsite brings all the benefits of a controlled production environment, including the use of ‘lean’ construction principles, stringent quality control, and superior process management. With multiple inspections throughout the process, and a final check prior to delivery, our custom bathrooms arrive defect free and ready for installation.

Every unit is WaterMark certified and has its own set of comprehensive Inspection Test Plans (ITPs) that are adhered to throughout the configuration process right through to installation.

#Installation

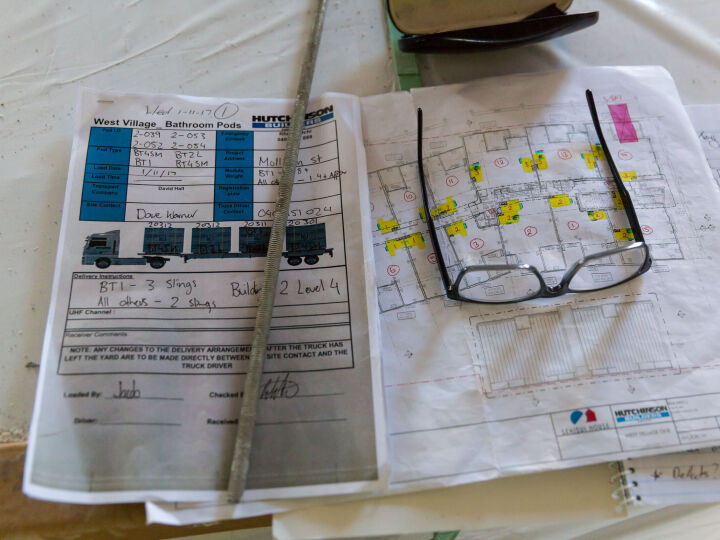

We coordinate all aspects of logistics, transport and installation of pre-configured suites. Depending on project size and site accessibility, the units can be installed directly onto the slab, or craned on to loading bays.

We provide all necessary training and support to give project teams the skills and knowledge to execute smooth installation. We also provide advice on the most appropriate lifting methodology – including structural engineering signoff – to ensure safe positioning on site and optimal crane efficiency.

01

Bathroomspickedfromstorage

02

Loadedontotruck

03

Truckfullyloaded

04

Truckdeparts

05

Trucktravelstosite

06

Truckarrivesonsite

07

Truckinplacetobeginunloading

08

Bathroomsliftedofftruck

09

Craneliftsbathroomsuptoloadingbays

10

Loadingbaysinplace

11

Bathroomsloadedintobays

12

Trolleyattachedtobathroom

13

Bathroomdeliverypointconfirmed

14

Bathroommovedintoplace

15

BathroomITPChecklistcompleted

16

Bathroominstallationcompletereadyforconnections

BathroomComplete

Process

Design

01

Procurement

02

Manufacture

03

FinalQA

04

Storage

05

Delivery

06

Install

07

Benefits

Quality

| Flexible, adaptable design | Controlled environment ensure water pressure tested |

| Full sized templates provided for detailed set-out and exact loading in-situ | Choose flush entry on rebated slabs or install directly on to slab with small step |

| All-inclusive bill of materials | Multiple inspections of every unit |

| Prototype built prior to construction | Glass reinforced concrete (GRC) base |

Cost Savings

Crane |  Hoist |

Traffic Control |  Overheads |

Amenities |  Machinery |

Reductions

Waste |  Onsite Labour |

Defects |  Finishing |

TheskyisthelimitforHutchieswithnew&innovativecustombathroomshelpingchangethewaywebuild.

Hutchies'CustomBathroomProductionFacility,YatalaQLD